It’s been a long time, perhaps even days, making, sanding, or cutting and then putting together your woodworking piece. It looks excellent; however, it’s still not finished.The final step is the application of a wood finish, which can safeguard your work and enhance its appearance. There are so many choices that are available, from polyurethane finishing oils. rganiWhatls. What do you need to consider when choosing the best one? This guide will take you through different kinds of finishes for wood and will help you choose the right one for your particular project.

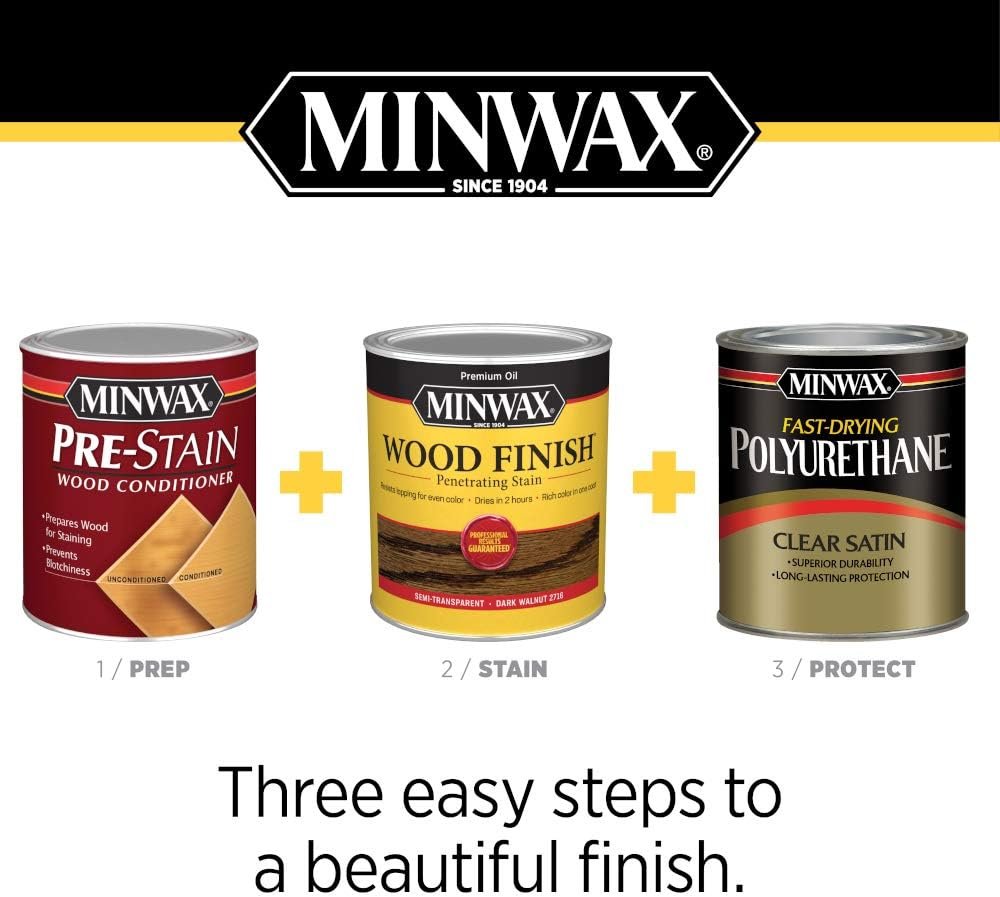

Knowing the distinction between different product types is essential. There are terms such as “wood stain vs. wood finish,” and you find yourself asking if they’re similar. Stains are designed to give the wood a color, and a finish serves as the protective coating that is applied to topcoats. Certain products, such as MiPolyshades, have both; however, for the vast majority of projects, there are two distinct steps.

Top Picks

# | Product | Title | Rating | |

1 |  | |||

2 |  | |||

3 |  | |||

4 |  | |||

5 |  |

The Main Categories of Wood Finishes

The wood finishes are categorized in a variety of types, each having distinct particulars. Knowing these categories will allow you to make a decision. The most commonly used kinds of wood finishes are the use of waxes, oils, lacquer, shellac, and varnishes, such as polyurethane.

Oil Finishes: Enhancing Natural Beauty

They are penetrating, which means they penetrate the wood fibers instead of creating a thin film on the surfaces. It results in a natural finish for wood that highlights the grain of the wood and gives wood a warm and thick appearance. The wood finish of oiled linseed oil or tung oil is the most well-known and traditional alternative.

- Danish oil wood finish It’s an extremely popular option for those who are new to woodworking since it’s a mixture of varnish, oil, and thinner, which makes it a breeze to apply. It has a matte natural appearance and some extra protection over the pure oil.

- Linseed Oil and Tung Oil: These oil-based oils are pure and penetrate well. They can be very effective in bringing out the character of wood. They offer only minimal protection from moisture and scratches and will require reapplying them regularly. The process of finishing wood using boiling linseed oil can be an old-fashioned method to achieve the classic hand-rubbed appearance.

- Hardwax Wood Finish Items such as Osmo wood finish as well as Rubio Monocoat combine plant-based oils and waxes. They provide long-lasting, ting, easy-to-repair, and safe-for-food wood finishes that are simple to apply and keep. These finishes are perfect for floors as well as furniture.

Wax Finishes: A Traditional and Simple Approach

A finish made of wax, for example, like the beeswax finish for wood, is among the oldest ways to protect wood. It’s quick and easy to apply and provides the wood with an ethereal, soft luster. Apply it directly to the surface of wood, or on top of an additional finish such as the shellac finish or a penetrating oil in order to provide an extra coating of protection and shine.

Beeswax finishing is non-toxic, which makes it a safe wooden finish that can be used on items such as cutting boards, wooden bowls, and even cutlery.But a finish with a wax coating does not last long. It is not very resistant to scratches or heat. In addition, it is required to be reapplied often to preserve its protection qualities.

Shellac: The All-Natural Film Finish

Shellac finishes Wood is a natural resin that forms protection on the surface of wood. It’s a popular choice for its warm amber-colored tone and its capacity to dry fast. It is available in a variety of cuts and typically sold as pieces that dissolve in denatured alcohol. Shellac is an incredibly versatile finish.

It’s a great sealer and is frequently utilized as a base coating underneath other finishes such as polyurethane or lacquer. Although it offers good protection from water spots, it’s vulnerable to harm from the heat and alcohol. Shellac finishes are an excellent choice for high-end furniture as well as antique restoration.

Lacquer: The Professional’s Choice for Durability

When you consider the high-gloss wood finish you see for furniture that is most likely professionally designed, you’re thinking of lacquer. The lacquer finish on wood is a quick-drying, long-lasting choice that’s usually used with a sprayer. It gives a tough and durable surface, which can vary from matte to high-gloss.

Traditional lacquers contain solvents, and water-based, wood-finishing alternatives are becoming more popular and less prone to VOCs. Lacquer can be a good alternative for tables, cabinets, or other items that will get a lot of usage; however, its speedy drying times and method of application can prove difficult for those who are new to the process.

Varnish & Polyurethane: The King of Protection

To ensure the best durability, you can’t beat varnish. The most popular varnishes today are polyurethane-based. Polyurethane finishes provide an extremely durable, thick plastic coating that is extremely impervious to heat, water solvents, scratches, and heat. It’s the most suitable wood finish for tables and kitchen countertops and flooring finishes.

Finishes made of polyurethane come in water-based as well as oil-based formulations.

- oil-based polyurethane: This kind of wood has an amber-colored shine and is very robust. It can take longer to dry and also has a distinct smell when it is applied.

- Water-based Polyurethane: A water-based polyurethane finish for wood that dries quickly, is odorless, and is clear, without getting yellowed in the course of time. It’s an ideal transparent finish for light-colored timbers, such as maple. Although it’s not as durable as the oil-based version, modern formulas like Varathane Diamond Wood Finish are exceptionally durable.

For those who require an outdoor wood finish for their outdoor furniture or the longest-lasting surface for tabletopsmade of wood, typically, polyurethane will be an answer. It’s available in different types of sheens, including matte and satin finishes to high gloss and semi-gloss.

How to Choose the Right Wood Finish for Your Project

Once you are aware of the many types of wood-finishing products, how can you determine which one you should use? Think about these things:

- The project’s use: Will the item be used as a display shelf or table for the kitchen? If you are dealing with items that get a lot of traffic, it is necessary to have a sturdy waterproof finish such as polyurethane. To create an attractive piece, an oil-based or wax finish may be the best option. Outdoor wood projects should seek out the exterior wood finish with UV protection. This could be spar varnish or special outdoor oil.

- Food Safety When you’re working on a cutting table, wooden knife, or any other toy that children play with, you’ll need a food-safe finish for wood. Pure linseed oil, raw tung oil, beeswax, or shellac and other specialized items such as Tried & True Wood Finish or a salad bowl finish are all great options that are not harmful.

- desired look: Do you desire a shiny wood finish or a soft, natural, organic look? If you want a glossy finish, lacquer is the best option. If you want a smooth or hand-rubbed appearance, think about Danish oil or the wax finish. The kind of wood is important; a clean finish maple can be different than a darker walnut finish.

- Easy to Use: Are you an absolute beginner or a seasoned finisher? The wipe-on and oil finishes are extremely user-friendly. Spraying lacquer on, however, will require the use of more tools and expertise. Learn the directions for applying every product you purchase.

Related Articles

Tips for a Perfect Finish

- The preparation is the most important thing: the quality of your finished product is directly dependent on the quality of the sanding. The project can be sanded smoothly using the various. Prior to applying the finish, ensure that the surfaces are clean of dust.

- Test Initial: Test the finish you are considering with a piece of the wood. It allows you to check the final appearance and color before you commit to your plan.

- Apply thin coats: Whether you’re wiping, brushing, or even spraying, it’s best to apply a few thin coats instead of one large one. It will result in a smoother finish as well as more efficient drying.

- Be sure to follow the drying times: Be patient and let the finish fully cure according to the specifications of the manufacturer. Doing it too quickly will result in the finish becoming sticky and soft, which can easily be damaged.

Selecting a wood finish does not necessarily have to be difficult. When you consider your project’s requirements and the style you wish to create, you’ll be able to be confident in selecting a finish that offers the protection you need and provides beauty for a long time into the future.

[…] Right Wood Finish […]